COMPRESSION MOULDING

Reffay: SMC Thermoset Compression / Composite Compression

An expert in compression moulding for several generations, REFFAY SAS is fully conversant with the techniques for processing SMC thermosets and SMC composites, as well as monitoring industrialised production. It processes a wide variety of materials, in particular certain thermosetting materials such as SMC (composites), requiring a high level of technical expertise.

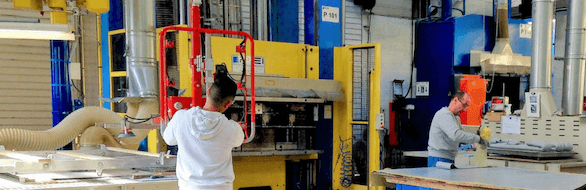

Our machinery: 500 T vertical clamping press

Deburring of a composite part

Our "compression moulding" technical processes

Composites / Thermoset (SMC) moulding of parts

Processed materials

SMC

Sheet Molding Compound