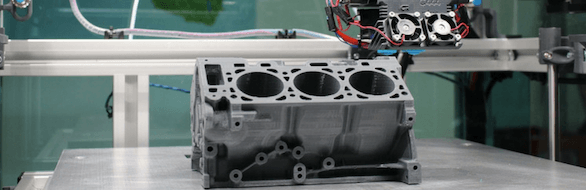

Why choose 3D printing?

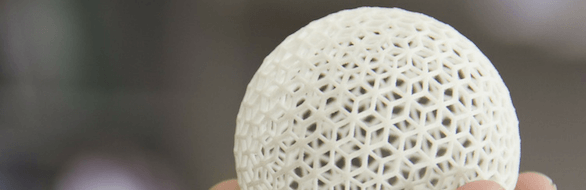

Producing a prototype is an essential stage in the development of a part. The manufacture of plastic prototypes reduces the risk of design errors and saves time in marketing the product. 3D-printed models and mock-ups offer many advantages, because with this technique they can be produced quickly and cheaply for:

- testing ergonomic use,

- test assembly and finishing,

- test the fit of components and their purpose,

- test the design of the part

Once the 3D printed model has been produced, it is possible to alter the design, materials, dimensions, shape, assembly, colour, industrialisation and robustness based on the results obtained during the various tests.

Reffay, the 3D printing specialist, can help you design your part and produce your 3D printing model.