THERMOSET INJECTION MOULDING

Reffay: experts in thermoset injection moulding

REFFAY SAS has been a thermoset injection moulding company for several generations, and is fully conversant with plastic injection moulding techniques and the monitoring of industrialised production. It processes a wide range of materials, in particular certain thermoset materials that require highly specialised expertise.

Thermoset injection press

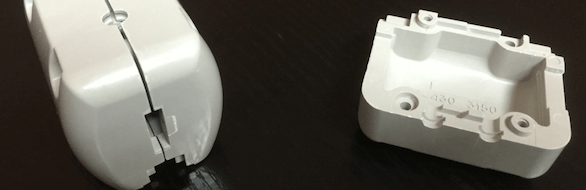

Example of parts - thermoset injection moulding

Reffay, thermoset injection moulding experts

Thermosetting injection moulding materials

Processed materials

BMC

Bulk Molding Compound

CIC

Continues Impregnated Compound